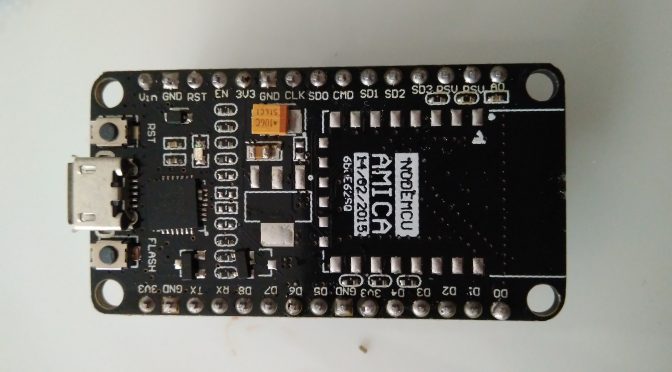

I wanted to try reflow soldering in kitchen owen. I had two boards – one with working ESP12 module (left) and one with working base board (right):

Desoldering working module

I attached 4 screws so I can stand the board on them and one to create force to separate the module from board I put the board into owen preheated to 200 degC

I put the board into owen preheated to 200 degC Few minutes later…

Few minutes later… I opened the owen, shaked the board and the module came off. I let it there for a few more minutes.

I opened the owen, shaked the board and the module came off. I let it there for a few more minutes.  Then I shaked it again to desolder more components.

Then I shaked it again to desolder more components. Now I had working module to be soldered to the target borad.

Now I had working module to be soldered to the target borad.

Preparing target board

This is where it screwed up. I repeated previous steps except of shaking. When the board was heated up, I tried to remove the module. Unfortunately, I didn’t have the right tool (pliers) and moved few other components: And this is the end. It was not worth the effort of soldering everything back to it’s place.

And this is the end. It was not worth the effort of soldering everything back to it’s place.

Next time I’ll make sure I have all needed tools before beginning and pay more attention when the board is hot – it’s very, very, VERY easy to displace all components.

So sorry man…

I don’t regret it, it was an interesting experience and value of these boards was almost zero.

Anyway, wish you more accuracy, when soldering this way )))

BTW, here is guy desolder some pieces by using regular halogen car lamp: https://www.youtube.com/watch?v=Nl60oEhsfB0

Video is on russian, but you could see all clearly.